To ensure that our customers benefit from the latest technological advancements, we consistently invest in industry-leading levels of research and development as a percent of sales, regardless of economic conditions. In fiscal 2011 alone, we invested nearly $1 billion to enhance legacy systems and create leading-edge products that meet emerging customer needs.

Increasing safety

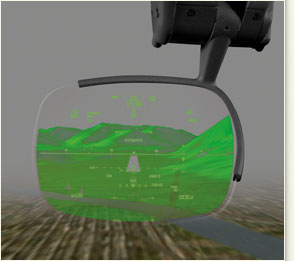

Pilots flying in low-visibility environments traditionally need to shift their focus from windshield to head-down flight displays and back, creating potential safety hazards. As the only company integrating synthetic vision into a head-up display (HUD), our pioneering technology creates a head-up, eyes forward virtual view of the outside world including reliable, real-time, computer-generated renderings of terrain, obstacles and runways. Pilots can now "see" through darkness and fog, enabling them to safely fly in conditions that would not otherwise be possible. Rockwell Collins joined an elite group when our synthetic vision on a HUD was named a runner-up in the Transport category in the 2011 Wall Street Journal Technology Innovation Awards.

Empowering natural product interfaces

In 2011, Rockwell Collins unveiled the industry's first touch-control primary flight displays for business jets and turboprop aircraft, which will be available on our Pro Line Fusion avionics system. The touch-controlled, icon-based functionality on the main displays helps keep pilots' attention focused up and forward for safer, more efficient flying. For example, when programming the flight management system, instead of entering information on a console-mounted keypad, pilots can redirect to a graphically displayed waypoint or destination with a single swipe of a finger. Other simple gestures directly on a map display control panning and zoom features. The touch-control primary flight displays and intuitive, icon-based controls make it even simpler for pilots of any background to navigate their aircraft more efficiently.

Quickening the pace of innovation

To accelerate the journey from concept to product delivery, our Advanced Technology Center uses rapid prototyping. Rapid prototyping helps us quickly develop and demonstrate game-changing technologies that address our customers' most critical needs. Our ANT-7000 C-band antenna is one such example.

Traditional directional airborne antennas are typically mechanical dishes that swing and point to communicate. As a result, manufacturing is expensive and communications are limited to one point at a time, restricting the number of pilots and soldiers that can be reached at any given time. Their large size and weight also negatively impact aircraft aerodynamic efficiency. Using rapid prototyping and incorporating customer feedback along the way, the ANT-7000 C-band antenna now provides high data throughput at half the weight and 20 percent of the cost of traditional airborne antennas. Its simple electronic switched network array enables almost instantaneous multidirectional communications with multiple points at one time. As a result, a communications network can now be established with a single ANT-7000 antenna versus requiring multiple traditional antennas. Aerodynamic efficiency of the aircraft is greatly increased as well. In less than a year, the solution was matured from concept to prototype to testing and product delivery to the customer. The antenna was recently recognized as a 2012 Aviation Week Innovation Challenge award finalist.