Support Equipment

DLS offers a number of accessories

that will assist in troubleshooting, testing, integrating,

installing, and maintaining your MIDS terminal. The links (at

left) will provide an introduction to specific DLS Support

Equipment available.

Key

areas of support equipment include:

Flight

Line/Forward Area Support Equipment

Intermediate

Level Support Equipment

Interface

Simulator Support Equipment

Power and Cooling

Custom Cable

Sets

Diagnostic and Simulation Software Packages

§

The Multifunction Integrated Test System (MITS) is

the latest addition to our DLS Link 16 Support

Equipment product line.

This system utilizes the latest generation

ruggedized tablet computer with colored flat screen

monitor - allowing the user to verify operational

terminal status on or off the aircraft.

The pen based tablet computer is easily hand held

(9 x 12.5 x 3, 5 lbs) and is ruggedized for

flight line operation. Operating temperature range

is -40˚ C to +70˚ C and the computer is sealed

against rain and dust.

Multifunction Integrated Test System

Features include:

Terminal Software Loader/Verifier

Network File Loader

Terminal Control/Monitor/Diagnostics

BIT Analysis

Windows XP on Tablet computer

Loads/Verifies core, I/O and MSG software

Provides two levels of status displays

Exercises Built-In-Test and interprets

results for field maintainers

Accesses MIDS diagnostic data for

troubleshooting in back-shop

Can read and write terminal data per the

Air Force specified standard format

Interfaces with support ports

SSPK is hosted in users laptop PC, where

other Link-16 software tools may exist

User-friendly graphical interface with

self-contained help

Intermediate Level Support Equipment <<Back to Top

The recently introduced Mobile Integration & Test Environment (MITE) system can provide a Line Replacement Unit (LRU) test capability with fault isolation to the Shop Replacement Unit (SRU) module. MITE identifies the faulty SRU which is then replaced and returned to the Depot for repair. The terminal LRU is then retested under a Repair Verification Test Procedure ensuring that the terminal is ready for service.

Mobile Integration & Test Environment (MITE)

system

Two Person Lift

19" Rack Enclosures

Displays: Dual 17" SXGA

In addition to the return-to-service capability, the MITE can provide:

-

Real time Terminal status and performance monitoring

-

Terminal initialization and control

-

Visibility into Terminal operation via the 1553 bus

or Support Port -

BIT initiation and monitoring

-

Access to software maintenance parameters

-

Reprogramming of Terminal Software Programs

(maintenance updates) -

Rapid data recording for post-test analysis

-

Enhanced troubleshooting

-

Recording and analysis of Terminal data

-

Situational display and scenario generation

-

Transmit and receive of TADIL-J messages

-

Windows-based user interface

Multifunctional Information Distribution System (MIDS) Interface Simulator (IS)

Multifunctional Information Distribution

System

(MIDS) Interface Simulator (IS)

-

The MIDS interface simulator (MIS) is the primary integration tool used by European platform integrators. It is a mature design with more than thirty systems deployed.

-

The MIS is capable of generating and evaluating scenarios in either of two operational modes.

-

In terminal simulation mode, the MIS controls the operational flight program hosted on commercial off-the-shelf (COTS) hardware. The MIS may also host these programs on MIDS SRUs (flight hardware).

-

In network simulation mode, the commercial hardware operates as a host platform while providing for the mounting, cooling and power provisions of a MIDS terminal.

-

Whatever mode of operation is selected, the testing effort will be maximized as a result of the integration of the MIS and the operational flight hardware and software.

§Power and Cooling <<Back to Top

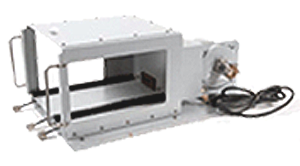

This ensures accurate alignment of the cooling tray airflow ports to the airflow inlets on the MIDS and RPS. Front hold downs are provided to secure the units; two for the MIDS and one for the RPS.

|

Height 9.74

24.74 cm

Width 13.82

35.10 cm

Depth 25.00

63.50 cm

Weight (approx.) 20 lbs

(excluding MIDS LVT and RPS)

25 lbs (w/ 19 rack mount

adapter plate)

Electrical input 115/120

VAC

50/60 Hz

Power 50/60 Hz

230/240 VAC 50/60 Hz

50/60 Hz

Available Customer

Support / Warranty Provided

|

|

This unit is rack mountable in a standard 19 wide rack configuration. Adapter plates can be provided to meet existing mounting patterns. The cooling tray unit is designed to operate when supplied with 115/120 VAC 60 Hz power (standard U.S. operation). A second version of the cooling tray will operate when supplied with 230/240 VAC 50 Hz power (European/Asian operation).

Terms of Access | Privacy Statement